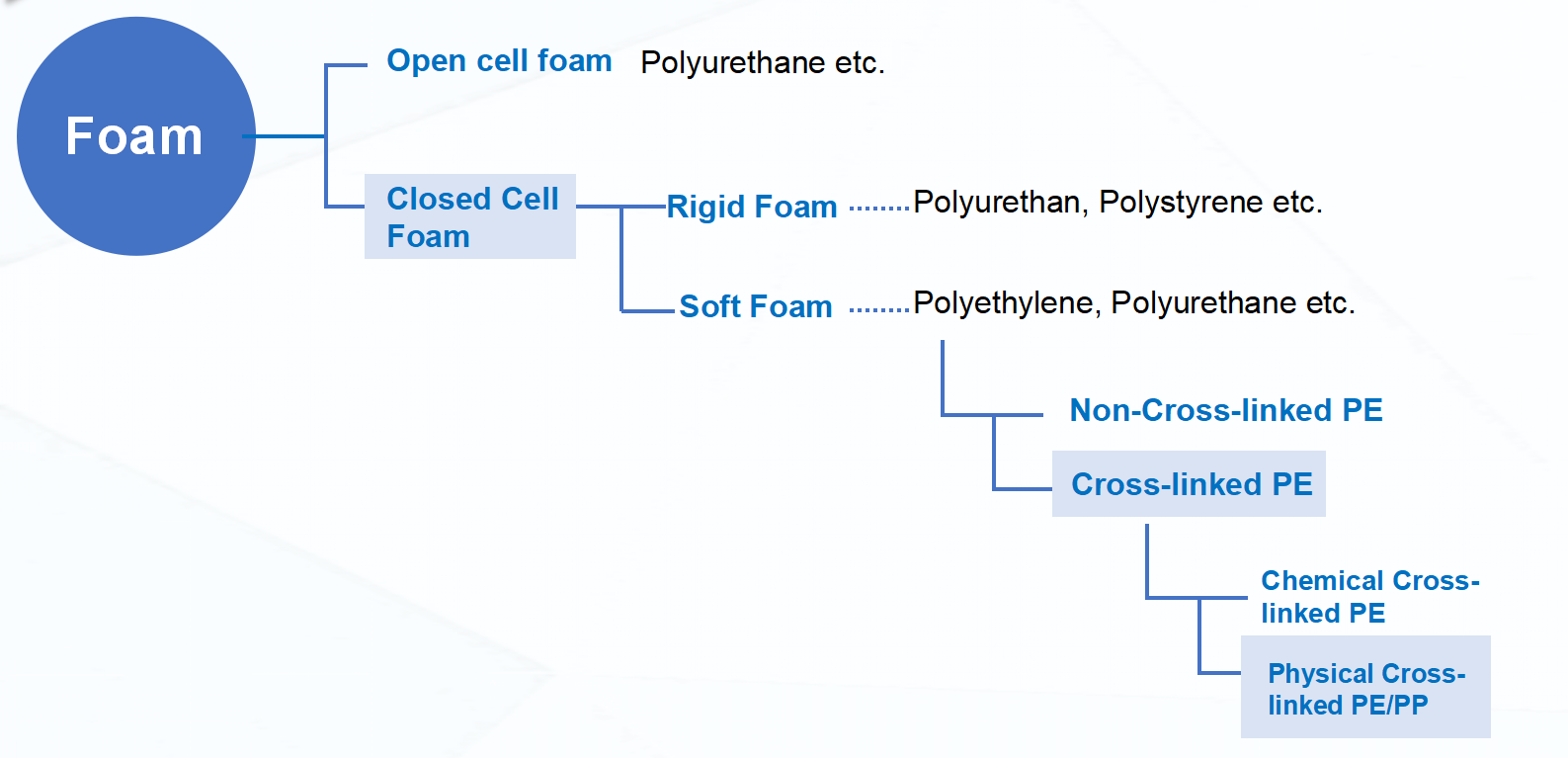

Yintoni i-IXPE/PP

Ugwebu

Igwebu luhlobo lwemveliso yeplastiki apho amaqamza omoya asasazwa khona ukuze abe neentunja.Igwebu liqulethe umoya omninzi kwaye ngenxa yoko likhaphukhaphu kwaye ligqwesile kwi-cushion kunye nokufakwa kwe-thermal.

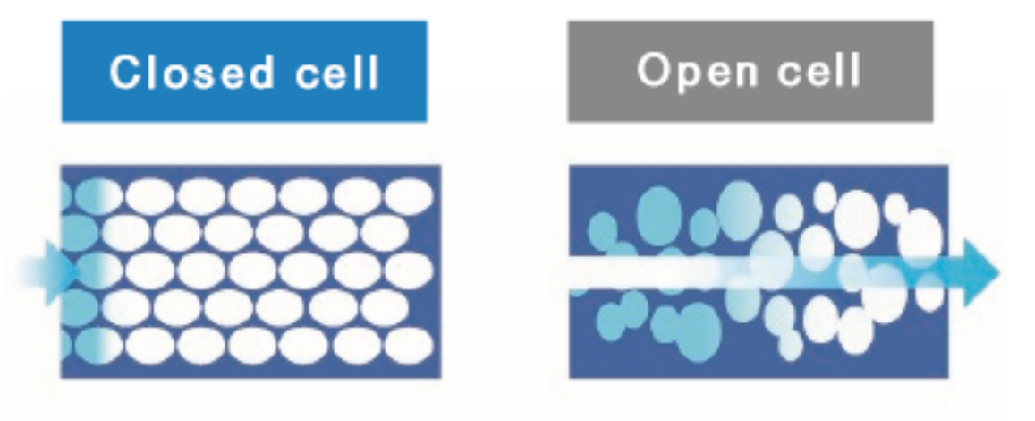

I-Foam evaliweyo

Ngaphakathi kolu hlobo lwe-foam, ama-bubbles angaphakathi azimele, awaxhunyiwe omnye komnye (iseli evulekileyo).Iiseli ezivaliweyo aziwukhupheli lula umoya.Ngaloo ndlela, zi-bouncy, ngokukhawuleza zibuyisela isimo sazo sokuqala xa zicinezelwe, kwaye zixhathisa amanzi.

I-PE edibeneyo

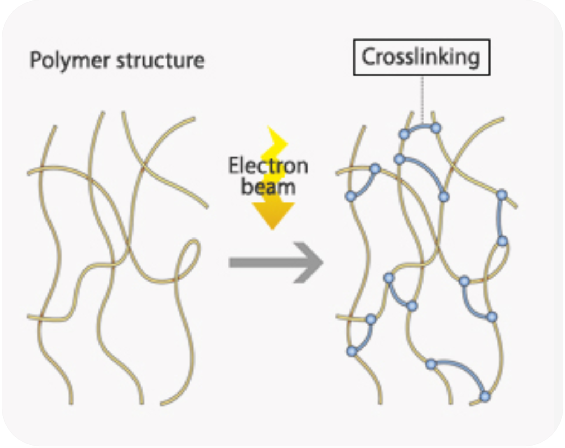

Ukusabela okudibanisa i-polyethylene ye-molecular chain.I-Crosslinking i-molecular structure iphucula amandla, ukuxhathisa ukushisa, ukuxhathisa imichiza, njl.

I-Physical Cross-linked PE/PP

Imiqadi ye-electron yaphula iibhondi zemolekyuli kwaye ivelise amabala asebenzayo epolymer.I-Irradiation crosslinking bubuchule bokudibanisa la mabala asebenzayo omnye komnye.Xa kuthelekiswa neemveliso ezinqamlezileyo zekhemikhali, i-irradiation-cross-linked products izinzile kwaye idibene ngokulinganayo.Iinzuzo ziquka indawo ethambileyo kunye negudileyo kwaye ilungile kuphuhliso lombala.

Inkqubo yokuVelisa

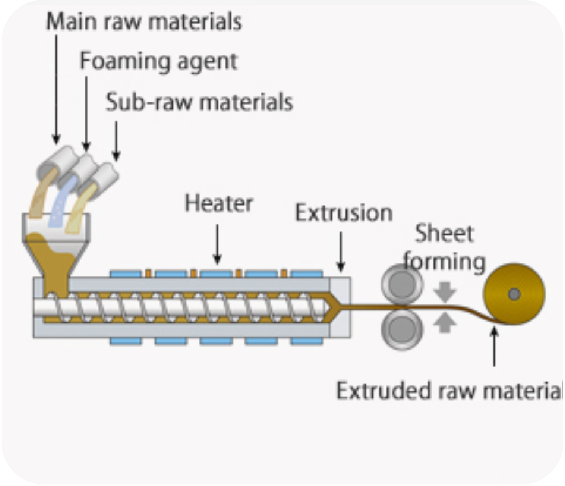

Extrusion

Izinto eziluhlaza (PE / PP) zixutywe kunye ne-agent evuthelayo kunye nezinye izinto kwaye zikhutshiwe kumaphepha.

Ukukhanyisa

Ukukhupha imiqadi ye-electron kwiipholima ukwenza iibhondi zemolekyuli.

Ugwebu

Amaphepha afakwe amagwebu ngokufudumeza, ukudala i-foam kunye nomthamo ukuya kumaxesha angama-40.

Ukumelana naManzi/Amandla okufunxa

Ukumelana naManzi/Ukufunxa

I-Polyolefin ye-resin esekelwe kwi-foam-cell evaliweyo inokufunxa okuphantsi kwamanzi

Ekubeni i-polyolefin i-lipophilic resin, yinto ephantsi-hygroscopicity.Iiseli kwi-IXPE / PP azixhunyiwe, ezingavumeli ukungena kwamanzi, zibonisa ukuchasana kwamanzi okugqwesileyo.

Amandla

Iqinile kodwa iyabhetyebhetye, inamandla okumelana nobushushu xa ithelekiswa namagwebu angadityaniswanga

Ukudibanisa i-molecular structure ye-polymer kunye neebhondi ezinjengeentambo ezibambeneyo ziqinisa ngakumbi iibhondi ze-molecular, ezikhokelela kwi-molecular lattice mesh structure, ukuphucula ukumelana nobushushu kunye namandla.

| Idityanisiwe | Ayidityaniswanga | |

| Ireyithi yoKwandiswa | Amaxesha angama-30 | |

| Ukutyeba | 2 mm | |

| Amandla okuqina (N/cm2) *2 | 43 | 55~61 |

| Ukwandiswa (%)*2 | 204 | 69-80 |

| Amandla eenyembezi (N/cm2)*2 | 23 | 15–19 |

| Ubuninzi beTem yokuSebenza*3 | 80℃ | 70℃ |

I-Thermal Conductivity Thermal Insulation Heat Resistance

I-Thermal Conductivity

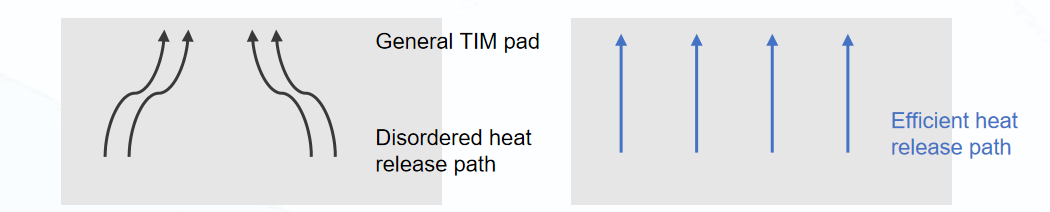

I-Thermal conductive filler elungiselelwe ngokufanelekileyo ifezekisa ukuhanjiswa okuphezulu kwe-thermal

Silawula i-orientation ye-anisotropic thermal conductive filler ukwenza iindlela ezisebenzayo zokukhupha ubushushu, ukufikelela kwi-conductivity ephezulu ye-thermal kunye nokuthamba.Ukongeza, ukubunjwa kwethu kwezinto eziphathekayo kuhlanganiswe kuphela kwezinto zokufakelwa kombane kunye ne-siloxane-free resins, ukunciphisa umngcipheko wokukhubazeka kwezinto ze-elektroniki ukuya kwinqanaba eliphantsi kakhulu.

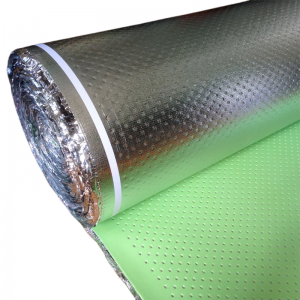

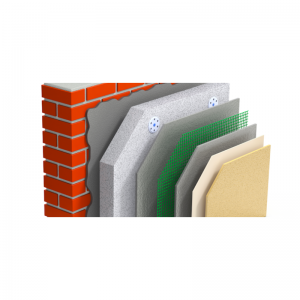

I-Thermal Insulation

Igwebu eliqulethe isixa esikhulu somoya kunye neconvection encinci ekhokelela ekuqhubeni kwe-thermal ephantsi kunye nokusebenza okuphezulu kwe-thermal insulation.

Iiseli ezivaliweyo kwi-foam zinciphisa ubungakanani be-convection yomoya, ziqhuba ubushushu obuncinci, obubonelela ngokugqwesileyo kwe-thermal.Ngokwahlukileyo kuboya beglasi kunye ne-foam eqinile, i-foam iguquguquka kakhulu kwaye kulula ukuyifaka.Ngoko ke, ifanelekile kwii-insulators zokuzalisa iindawo ezincinci kakhulu ezindlwini kunye noomatshini abahlukeneyo.

Ukumelana nobushushu

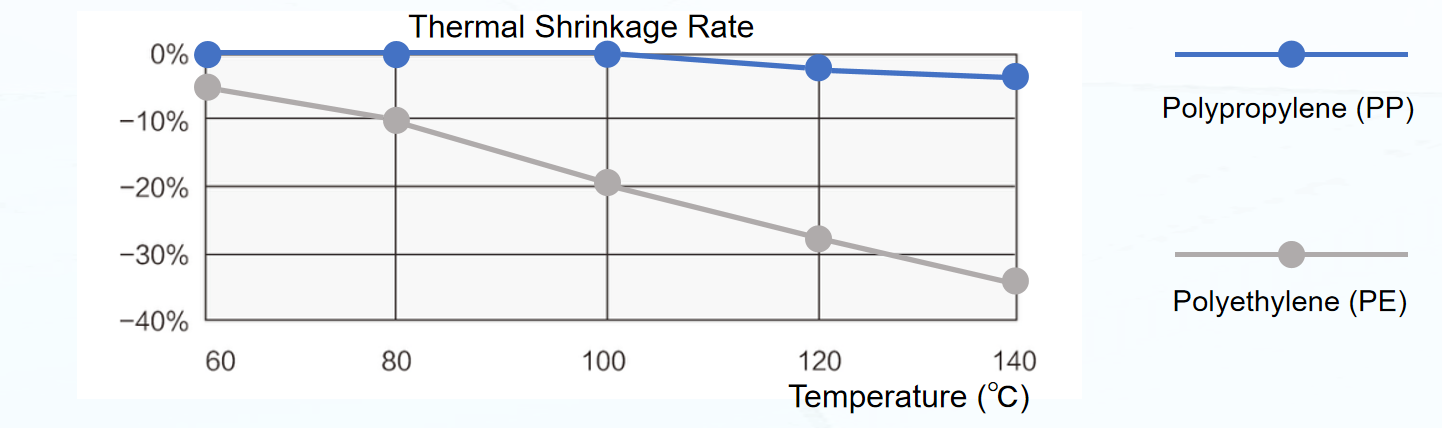

Ngokuxhathisa ubushushu obugqwesileyo, i-polypropylene resin ine-shrinkage encinci ye-thermal nakwinqanaba eliphezulu lobushushu

Umlinganiselo ubonisa ukuba i-foam iguquka kangakanani ngobukhulu kumaqondo okushisa ahlukeneyo xa ishushu ngaphandle kokusetyenziswa kwamandla angaphandle.Ngelixa i-polyethylene ugwebu lukhubaza xa lutshiswe ukuya kuma-80°C okanye ngaphezulu, i-polypropylene foam inobuxhakaxhaka obugqwesileyo bokumelana nobushushu obunesantya sokushwabana kwe-3% okanye ngaphantsi nakwi-140°C.

Ukutywina Ukukwazi ukuguquguquka Ukuguquguquka

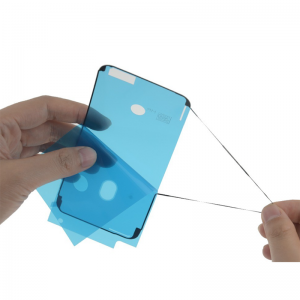

Amandla okutywina

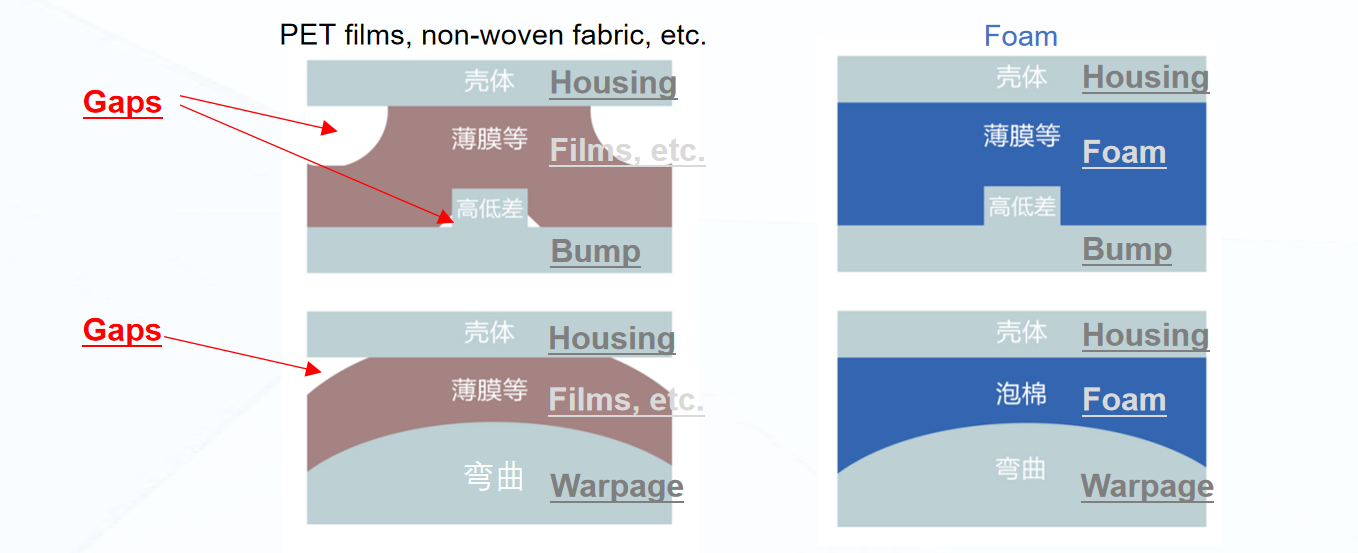

Ngokuguquguquka kwayo, i-foam itywina iindawo ezingalinganiyo okanye ezibukhali

Ipropati yokutywina ye-sealer enjengeeteyiphu ichatshazelwa kakhulu kungekuphela nje ngeempawu zezinto eziphathekayo kodwa kunye nokudibanisa kwayo okusondeleyo kunye nomphezulu ongalinganiyo we-adherend.Isixhobo esinokuguquguquka okuphezulu sisusa izithuba ngokubambelela kwaye siqonde ukusebenza kokutywinwa okuphezulu.

Thelekisa nezinye izinto kwipropathi yokutywina

I-foam ivala iindawo ezingalinganiyo kwaye izalise izikhewu ngaphakathi kwendlu

Ukuguda

Umphezulu ococekileyo kunye nococekileyo xa kuthelekiswa ne-foam yekhemikhali enqamlezileyo, ilungele ukunamathela kunye nokwaleka

I-Electron beam crosslinking ikhawulezisa ii-electron ezinombane ophezulu kwaye izikhuphela kumaphepha.Ii-elektroni ze-beam ngokulinganayo kwaye zingena ngokuzinzileyo kwiphepha ngalinye, okukhokelela ekudibaniseni okudityanisiweyo kunezinye iindlela.Ivumela nokuba kugwetywe ugwebu okudala umaleko ogudileyo womphezulu olungele ukuncamathela kunye nokwaleka.

Ukuba bhetyebhetye

I-resin's intrinsic softness kunye ne-closed-cell structure inika i-elasticity efanelekileyo kunye ne-cushioning

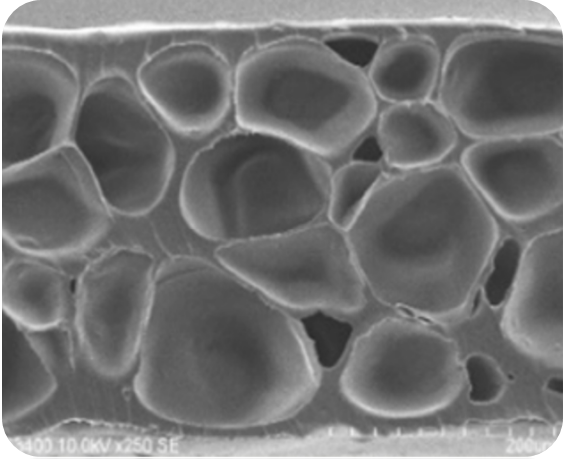

Iseli ye-electron-crosslinked sheets iya kuqulatha i-inflate kwinkqubo yokukhupha amagwebu kamva.Iiseli ezinamaxesha ahlukeneyo okwandisa zenza isakhiwo seseli evaliweyo apho zonke iiseli zihlulwe ngeendonga.Ulwakhiwo lweeseli ezivaliweyo lune-cushioning ekhethekileyo kunye nokufunxa ukothuka.Ukuba nokufunxeka okugqwesileyo okugqwesileyo nokuba nobukhulu obuncinci, amaphepha e-IXPE/PP asetyenziswa njengepakethe yokukhusela izixhobo ezichanekileyo.

Ukusebenziseka

Thermoformability

Umthwalo ophantsi wokusiNgqongileyo

Iimpawu zoMbane

Ukusebenziseka

Uzinzo lwemilo olugqwesileyo luqonda ukusetyenzwa ngeendlela ezahlukeneyo

Ukusebenzisa i-thermoplastic polyolefin resin, ugwebu lwethu lunokutshintsha ubumanzi bepolymer ngokutshintsha ubushushu.Ngokufudumeza kunye nokunyibilika, kunokuncamathisela ezinye izinto okanye ukuguqula i-foam.Ngokusebenzisa inzuzo yokuzinza kwimilo kwiqondo lokushisa legumbi, inokunqunyulwa ibe yimilo enzima.

Imizekelo ephambili yokuqhuba

● Ukusika (ukutshintsha ukutyeba)

● Lamination (ubushushu ukuwelda)

● Ukusika (ukusika ngomngundo)

●I-Thermoforming (ukwenza i-vacuum, ukubumba ukucofa, njl.

Thermoformability

I-IXPP imelana nobushushu obuphezulu ngexesha lokubumba, ivumela ukutsaleka okunzulu kakhulu

I-Polypropylene (PP) inendawo ephezulu yokunyibilika kune-polyethylene (PE).Ngokumelana nobushushu obugqwesileyo nakumaqondo obushushu aphezulu ngexesha lokubumba, iPP inokufikelela kokubini okugqwesileyo kwe-thermoformability kunye ne-cushioning.Ngokukodwa, i-PP isetyenziswa ngokubanzi kwizixhobo ze-automotive trim yangaphakathi kunye neetreyi zokukhusela iziqhamo.

Umthwalo ophantsi wokusiNgqongileyo

I-halogen-free, akukho gesi ezinetyhefu xa zitshisiwe

I-Polyolefin luhlobo lweplastiki efunyenwe ngokudityaniswa kwee-monomers (oko kukuthi ii-molecule zeyunithi) ezine-carbon-carbon double bonds.Ekubeni ingenayo i-halogens efana ne-fluorine kunye ne-chlorine, ayivelisi iigesi ezinetyhefu kakhulu xa itshiswa.

Iimpawu zoMbane

Isixa esikhulu somoya ngaphakathi kweeseli ezivaliweyo sinika amandla abalaseleyo e-dielectric kunye nemvume ephantsi

Ukwakhiwa kweeseli ezivaliweyo, apho umoya onamandla aphantsi e-dielectric uvalelwe kwiindawo ezincinci ezihlukeneyo, ubonisa amandla aphezulu e-dielectric.Ukongeza, i-polyolefin, enemvume ephantsi kakhulu xa kuthelekiswa nezinye iiplastiki zenjongo jikelele, ezenziwe kwisakhiwo esinomoya inika imvume engaphantsi.